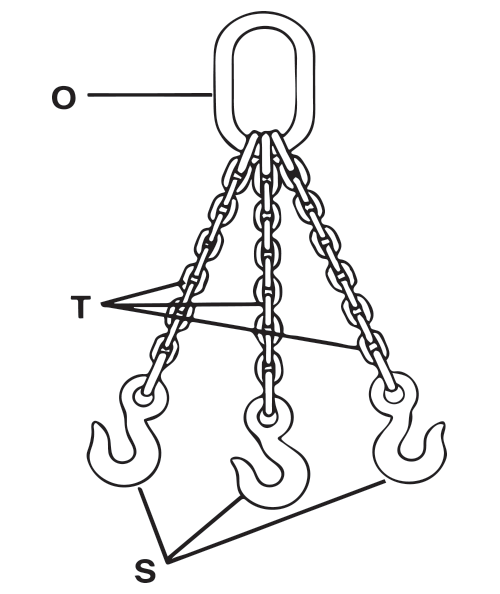

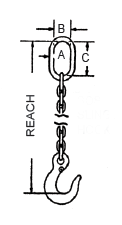

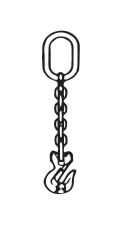

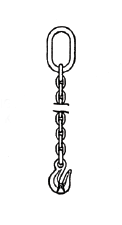

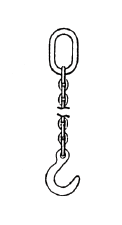

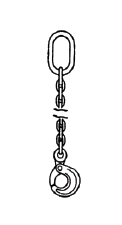

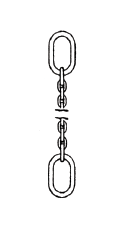

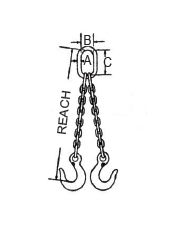

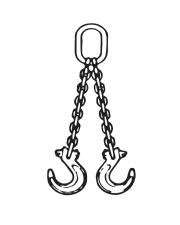

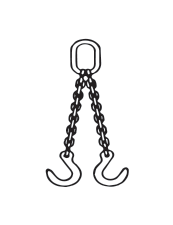

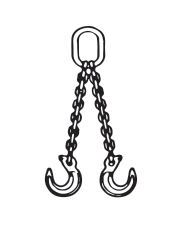

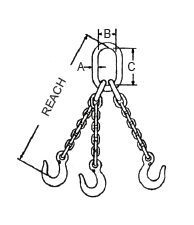

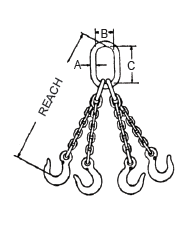

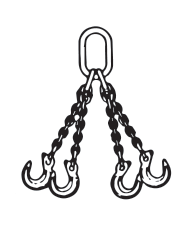

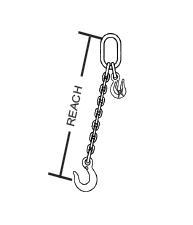

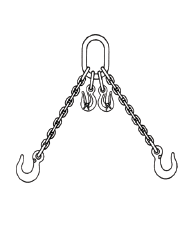

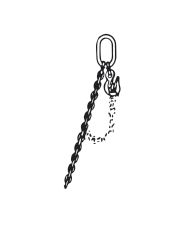

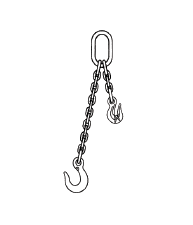

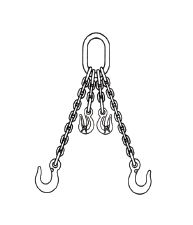

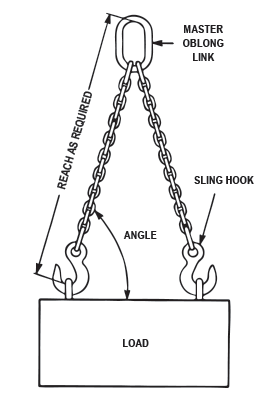

CHAIN SLING INFORMATION

Hanes Supply has a long history of providing quality chain slings to industry. We use CM® grade 100 Herc-Alloy® 1000 Chain and attachments along with Crosby® Fittings in the manufacture of our slings. In addition to the products you see here, we manufacture custom chain assemblies to your specifications. All Herc-Alloy® 1000 chain and attachments are black finish and/or color coded orange for easy, permanent identification. The chain is embossed with the grade (HA-1000).

A higher strength heat treated alloy steel chain, CM® grade 100 Herc-Alloy® 1000 chain is primarily used as a sling component for overhead lifting, but can be used in rigging and tie down applications where a lighter weight high strength chain is desirable. Recommended for overhead lifting by NACM, ANSI & OSHA.

Crosby® is considered the standard in the rigging industry. Crosby® products are manufactured with the highest design factors in the industry. These products are better able to withstand abusive field conditions because of the improved impact and fatigue characteristics designed into each item.

Before shipment, all HSI® chain slings undergo a succession of demanding quality control checks. Every sling is proof tested, registered and guaranteed for one year to be free from defects in materials and workmanship. A durable metal tag attached to the sling permanently identifies the grade, type, working load limit (at a specific angle of lift) and registration number of the sling.

Channellock® 426 Tongue and Groove Plier, 7/8 in Nominal, 3/4 in L C1080 High Carbon Steel Straight Jaw, 6-1/2 in OAL

Channellock® 426 Tongue and Groove Plier, 7/8 in Nominal, 3/4 in L C1080 High Carbon Steel Straight Jaw, 6-1/2 in OAL

Stanley® 33-716 FatMax® Reinforced Tape Rule with BladeArmor®, 16 ft L x 1-1/4 in W Blade, Mylar® Polyester Film Blade

Stanley® 33-716 FatMax® Reinforced Tape Rule with BladeArmor®, 16 ft L x 1-1/4 in W Blade, Mylar® Polyester Film Blade

Arrow™ HT50 Professional Heavy Duty Tomahawk Hammer Tacker, Flat Crown Staple

Arrow™ HT50 Professional Heavy Duty Tomahawk Hammer Tacker, Flat Crown Staple

Klein® D2000-9ST 2000 Heavy Duty Rebar Work Cutting Plier, 9-3/8 in OAL

Klein® D2000-9ST 2000 Heavy Duty Rebar Work Cutting Plier, 9-3/8 in OAL

Estwing® E324S Framing Hammer, 16 in OAL, Smooth Surface, 24 oz Steel Head, Straight Claw, Steel Handle

Estwing® E324S Framing Hammer, 16 in OAL, Smooth Surface, 24 oz Steel Head, Straight Claw, Steel Handle

DeWALT® Power-Stud®+ Powers® 7449SD1-PWR Expansion Wedge Anchor, 3/4 in dia, 10 in OAL, 7-1/2 in L Thread, Carbon Steel, Zinc Plated

DeWALT® Power-Stud®+ Powers® 7449SD1-PWR Expansion Wedge Anchor, 3/4 in dia, 10 in OAL, 7-1/2 in L Thread, Carbon Steel, Zinc Plated

BBI® 777037 All Threaded Rod, 3/8-16, 12 ft OAL, Steel Alloy

BBI® 777037 All Threaded Rod, 3/8-16, 12 ft OAL, Steel Alloy

BBI® 754072 Medium Split Lock Washer, 1/2 in Nominal, 18-8 SS

BBI® 754072 Medium Split Lock Washer, 1/2 in Nominal, 18-8 SS

Primesource® 8CTDSKR Sinker Nail, 17/64 in, 2-3/8 in L, 9 ga, Vinyl Coated, Smooth Shank

Primesource® 8CTDSKR Sinker Nail, 17/64 in, 2-3/8 in L, 9 ga, Vinyl Coated, Smooth Shank

Campbell® T3899724 Hitch Pin, 1/2 in dia, 4-1/4 in L Usable, Forged Steel, Zinc Plated with Yellow Chromate, 5 Grade

Campbell® T3899724 Hitch Pin, 1/2 in dia, 4-1/4 in L Usable, Forged Steel, Zinc Plated with Yellow Chromate, 5 Grade