Bonded abrasives are cutting and grinding tools created by fusing abrasive grains with bonding agents to form solid shapes like wheels, cones, or plugs. These tools are critical in various metalworking, construction, and manufacturing applications for cutting, grinding, deburring, and finishing. Unlike coated abrasives (such as sandpaper), bonded abrasives are rigid, durable, and designed for high-pressure tasks that require precision and efficiency. Hanes Supply provides a wide selection of bonded abrasives to satisfy the needs of both light-duty and heavy-duty operations.

Common Shapes, Sizes & Applications

Bonded abrasives are made in various shapes and sizes, each designed for specific tasks, machinery types, and materials. Choosing the right shape is crucial for achieving optimal performance, safety, and quality of finish. Below are the most common forms of bonded abrasives and their applications in real-world scenarios:

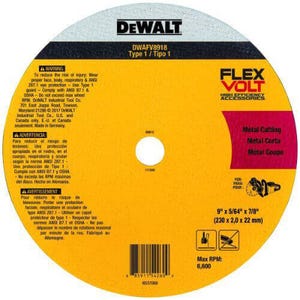

Straight Grinding Wheels (Type 1)

These are the most universal and widely used wheel shapes. Featuring a flat, circular design, straight wheels are utilized on bench grinders and pedestal grinders for surface grinding, sharpening tools, deburring, and stock removal. Available in sizes ranging from 4" to 14" or larger, they are ideal for light-duty and heavy-duty applications.

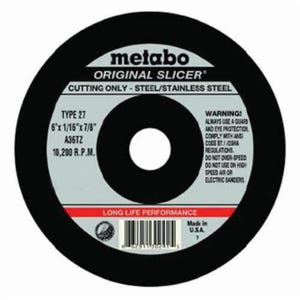

Cut-Off Wheels (Type 1)

Cut-off wheels are thinner and designed explicitly for slicing through metal rods, rebar, bolts, pipes, and other tough materials. They’re used with chop saws, stationary cut-off machines, and handheld angle grinders. Typical applications include fabrication shops, auto body repair, and construction sites.

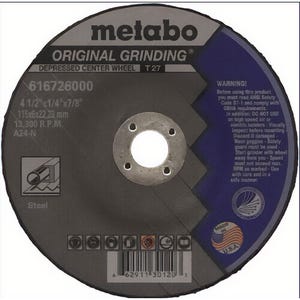

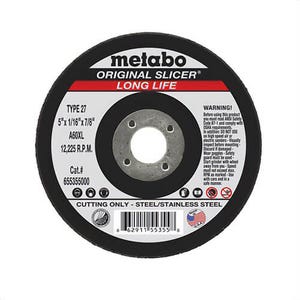

Depressed Center Wheels (Types 27 & 28)

Depressed Center wheels have a recessed center that allows them to be mounted flush on angle grinders. This design enhances operator control during edge grinding, weld bead removal, beveling, and blending. It is commonly used in metal fabrication, shipbuilding, and welding operations.

Cup Wheels (Type 11)

Shaped like an upside-down cup, these wheels provide a large grinding surface and are commonly used on vertical grinders for flat surface work, including stone polishing, concrete smoothing, and cleaning the surfaces of castings.

Mounted Points, Plugs, and Cones (Types 16, 17, 18)

These small-format abrasives are utilized in die grinders and rotary tools for precision tasks, including internal grinding, mold finishing, and detailed deburring in tight spaces.

Each shape is offered in a variety of diameters, thicknesses, and grit options to meet the needs of different tool types, operating speeds, and materials, making it essential across industries such as automotive, aerospace, construction, and metal fabrication.

Composition & How They're Made

Bonded abrasives are produced by combining abrasive grains with a bonding agent and shaping them into a specific form. The key components include:

• Abrasive Grains: The cutting agents include aluminum oxide, silicon carbide, zirconia alumina, ceramic alumina, and superabrasives such as CBN and diamond.

• Bonding Materials: The medium that binds the grains together. Common types include vitrified (glass-like), resinoid (phenolic resin), rubber, shellac, and metal.

• Fillers & Additives: These enhance performance characteristics like strength, porosity, and heat resistance.

After mixing, the mixture is shaped in molds and cured with heat or chemicals. The final product is a rigid, durable tool suited for aggressive grinding and cutting tasks with precision.

Bond Types & Their Advantages

The type of bond determines a wheel's cutting action, durability, and ideal applications:

• Vitrified Bonds: Made from clay and fired at high temperatures, these rigid and porous materials provide excellent precision and are ideal for surface grinding and internal cylindrical grinding, where minimal heat generation is crucial.

• Resinoid Bonds: These wheels are recognized for their flexibility and shock resistance, making them ideal for rapid material removal, cutting-off operations, and applications that require aggressive grinding.

• Rubber Bonds: Achieve smooth finishes and enhanced control, commonly employed for high-precision polishing and truing operations.

• Metal and Electroplated Bonds: Designed for superabrasive grains (CBN and diamond), these tools provide excellent wear resistance and are used in high-heat, high-pressure environments such as tool and die manufacturing.

• Other Bonds (Shellac, Silicate, Oxychloride): Used in specialized applications that require thermal sensitivity or unique chemical resistance.

Selecting the appropriate bond promotes longer wheel life, enhances results, and increases safety.

Grain Size, Wheel Characteristics & Selection

Grain size and wheel structure significantly influence the performance of a bonded abrasive.

Cup Wheels (Type 11)

• Coarse (10–24 grit): Fast material removal for rough grinding.

• Medium (30–60 grit): Blending and surface prep.

• Fine (80–200 grit): Finishing operations.

• Very Fine (220+ grit): Precision and polishing.

Grade (Hardness)

• Alphabetical scale (A–Z); softer grades (A–H) wear down more quickly but have self-sharpening properties. Harder grades (R–Z) are more durable and are used for prolonged grinding cycles.

Structure (Density)

• Open structures (low density) facilitate cooler grinding and chip clearance.

• Dense structures provide smoother finishes and a more aggressive cutting action.

Selection Factors

• Workpiece material (e.g., aluminum oxide for steel, silicon carbide for non-ferrous).

• Desired finish and removal rate.

• Machine type and operating speed.

• Bond strength and application environment (wet or dry).

Performance & Safety Considerations

Maximizing the performance of bonded abrasives depends on proper usage and safety practices:

Performance Tips

• Use the appropriate wheel speed (RPM) and pressure for your machine and material.

• Dress and true wheels regularly to maintain proper geometry and cutting action.

• Use coolant or lubricant to minimize heat in precision grinding.

Safety Guidelines

• Always check wheels for cracks or damage before use.

• Align the wheel’s RPM rating with your tool.

• Wear guards, face shields, gloves, and appropriate PPE during operation.

• Store wheels in a dry, temperature-controlled environment to avoid warping or bond degradation.

Following safety protocols increases product lifespan, safeguards workers from injuries, and protects equipment from damage.

Industrial Applications & Material Pairing

Bonded abrasives are essential in various industries and are suitable for different materials:

Metal Fabrication

• Aluminum oxide and ceramic wheels for fabricating steel and grinding pipes.

• Zirconia wheels designed for stainless steel and alloys.

Automotive & Aerospace

Precision wheels for grinding engine parts, deburring cast components, and cutting structural materials.

Construction

• Diamond and silicon carbide wheels are used for cutting concrete, tile, brick, and masonry.

Foundries & Machine Shops

Durable wheels for cleaning castings, removing flash, and sharpening tools.

Tool & Die Manufacturing

CBN and diamond wheels are designed for ultra-hard materials such as carbide, tool steel, and ceramics.

Selecting the appropriate abrasive for the task guarantees increased productivity, enhanced surface quality, and extended tool life.

Why Choose Hanes Supply’s Bonded Abrasives

Hanes Supply offers a comprehensive line of high-performance bonded abrasives sourced from trusted industry brands. Whether you’re performing rough stock removal or precision grinding, we have the right tool for the job. Our range includes wheels for every major application, from general-purpose metalworking to specialized cutting and finishing.

Channellock® 426 Tongue and Groove Plier, 7/8 in Nominal, 3/4 in L C1080 High Carbon Steel Straight Jaw, 6-1/2 in OAL

Channellock® 426 Tongue and Groove Plier, 7/8 in Nominal, 3/4 in L C1080 High Carbon Steel Straight Jaw, 6-1/2 in OAL

Stanley® 33-716 FatMax® Reinforced Tape Rule with BladeArmor®, 16 ft L x 1-1/4 in W Blade, Mylar® Polyester Film Blade

Stanley® 33-716 FatMax® Reinforced Tape Rule with BladeArmor®, 16 ft L x 1-1/4 in W Blade, Mylar® Polyester Film Blade

Arrow™ HT50 Professional Heavy Duty Tomahawk Hammer Tacker, Flat Crown Staple

Arrow™ HT50 Professional Heavy Duty Tomahawk Hammer Tacker, Flat Crown Staple

Estwing® E324S Framing Hammer, 16 in OAL, Smooth Surface, 24 oz Steel Head, Straight Claw, Steel Handle

Estwing® E324S Framing Hammer, 16 in OAL, Smooth Surface, 24 oz Steel Head, Straight Claw, Steel Handle

Klein® D2000-9ST 2000 Heavy Duty Rebar Work Cutting Plier, 9-3/8 in OAL

Klein® D2000-9ST 2000 Heavy Duty Rebar Work Cutting Plier, 9-3/8 in OAL

DeWALT® Power-Stud®+ Powers® 7449SD1-PWR Expansion Wedge Anchor, 3/4 in dia, 10 in OAL, 7-1/2 in L Thread, Carbon Steel, Zinc Plated

DeWALT® Power-Stud®+ Powers® 7449SD1-PWR Expansion Wedge Anchor, 3/4 in dia, 10 in OAL, 7-1/2 in L Thread, Carbon Steel, Zinc Plated

BBI® 777037 All Threaded Rod, 3/8-16, 12 ft OAL, Steel Alloy

BBI® 777037 All Threaded Rod, 3/8-16, 12 ft OAL, Steel Alloy

BBI® 754072 Medium Split Lock Washer, 1/2 in Nominal, 18-8 SS

BBI® 754072 Medium Split Lock Washer, 1/2 in Nominal, 18-8 SS

Primesource® 8CTDSKR Sinker Nail, 17/64 in, 2-3/8 in L, 9 ga, Vinyl Coated, Smooth Shank

Primesource® 8CTDSKR Sinker Nail, 17/64 in, 2-3/8 in L, 9 ga, Vinyl Coated, Smooth Shank

Campbell® T3899724 Hitch Pin, 1/2 in dia, 4-1/4 in L Usable, Forged Steel, Zinc Plated with Yellow Chromate, 5 Grade

Campbell® T3899724 Hitch Pin, 1/2 in dia, 4-1/4 in L Usable, Forged Steel, Zinc Plated with Yellow Chromate, 5 Grade