Non-woven abrasives are designed for professionals who need precise surface finishing without sacrificing part geometry. Made from an open-web structure of nylon fibers impregnated with abrasive grains and bonded with resin, these materials provide controlled action — removing rust, oxidation, coatings, and light burrs while delivering consistent surface finishes.

Unlike coated or bonded abrasives, non-woven options are less aggressive in cutting; they focus on conditioning and refining surfaces. This makes them perfect for metal fabrication, maintenance, and production settings where surface uniformity and part integrity are crucial. Hanes Supply provides a broad selection of non-woven abrasive products to assist at every finishing stage, from hand preparation to automated belt systems.

Bristle Discs

Bristle Discs combine flexible abrasive filaments with the open-web performance of non-woven construction. Their radial bristle design easily conforms to irregular surfaces and internal contours, making them ideal for cleaning welds, removing rust, or deburring complex parts.

Applications:

• Surface cleaning and finishing for metal, composites, or plastic.

• Removing paint, scale, and oxidation

• Polishing welds or joints without changing dimensions

Key Benefits:

• Consistent, controlled abrasion

• Cooler cutting with less loading

• Longer service life compared to wire brushes

When selecting a bristle disc, match the grit to the desired finish and ensure the disc size and arbor fit your grinder’s RPM rating.

Flap Brushes

Non-woven flap brushes are made with multiple abrasive flaps arranged around a hub. They provide consistent, even finishing on flat or contoured surfaces and are popular for achieving brushed or satin finishes on stainless steel and aluminum.

Applications:

• Blending welds and tool marks

• Finishing stainless steel sheet, pipe, or railing

• Cleaning before coating or painting

Advantages:

• Flexible design follows curved parts

• Non-loading open-web construction

• Delivers consistent satin finishes

Select brush density, grit grade, and width according to your workpiece size and the desired surface finish.

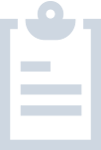

Hand Pads

Non-woven hand pads are the preferred choice for manual surface preparation, blending, or cleaning in tight spaces or on delicate materials. They replace traditional steel wool, providing consistent performance without rust or fiber contamination.

Applications:

• General cleaning, polishing, or scuffing

• Removing rust or oxidation from fittings and fixtures

• Surface prep before painting, bonding, or welding

Advantages:

• Conformable to corners and edges

• Non-marring and reusable

• Available in multiple grit grades for custom control

For versatility, keep various grades available — coarse for cleaning and fine or ultra-fine for final finishing or blending.

Non-Woven Abrasive Belts

Built for belt sanders and finishing machines, non-woven abrasive belts deliver continuous surface conditioning over large areas. They’re perfect for deburring, blending, and finishing sheet metal, tubing, and formed parts.

Applications:

• Grain finishing on stainless or aluminum sheets

• Cleaning and surface prep in fabrication lines

• Polishing before coating or plating

Advantages:

• Durable, consistent finish with reduced heat buildup

• Resists loading for longer belt life

• Flexible enough to follow contours or part geometry

Select the proper belt dimensions and grit to match your machine type, speed, and desired finish.

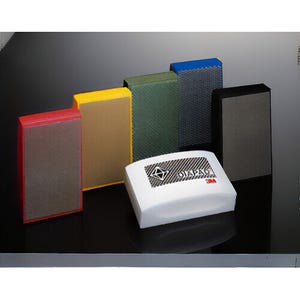

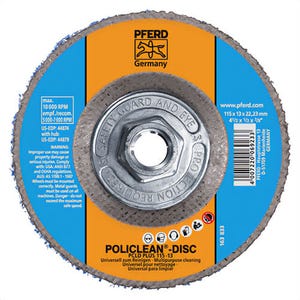

Non-Woven Abrasive Discs

These surface conditioning discs provide controlled cutting and a smooth finish on various metals. Used with angle grinders or orbital tools, they are effective for weld blending, rust removal, and cleaning parts.

Applications:

• Blending and finishing welds

• Cleaning pipe, fittings, or cast parts

• Removing coatings, rust, and light oxidation

Advantages:

• Cool running and non-loading

• Excellent for multi-step finishing processes

• Available in quick-change and hook-and-loop styles

Match disc size and backing type to your tool setup for optimal control and surface quality.

Non-Woven Abrasive Rolls

Abrasive rolls let you cut material to your desired length, making them a flexible, cost-effective choice for hand or machine use.

Applications:

• Hand sanding or machine feed systems

• Cleaning and finishing wide or irregular surfaces

• Cutting custom strips for tight areas or specialized fixtures

Advantages:

• Reduces waste through custom sizing

• Ideal for both dry and wet applications

• Consistent abrasive exposure throughout the roll length

Select width, grit, and material compatibility to meet your application demands.

Non-Woven Abrasive Wheels

Non-woven wheels, including unitized and convolute styles, are built for demanding surface conditioning, deburring, and finishing operations on bench or portable grinders.

Applications:

• Deburring edges and small components

• Cleaning welds and tool marks

• Creating uniform, brushed finishes on stainless steel or aluminum

Advantages:

• Maintains shape and balance at high RPM

• Cool cutting and long-lasting performance

• Consistent finish without smearing or gouging

Select the appropriate wheel type, density, and grit grade for your machine and material.

When to Choose Non-Woven Abrasives

Non-woven abrasives are designed to carefully balance efficiency and control, effectively removing surface contaminants while maintaining critical tolerances and shapes. Their open-web structure allows continuous airflow during use, reducing heat buildup and preventing discoloration or warping of the workpiece. This makes them especially suitable for polishing stainless steel, aluminum, and heat-sensitive alloys, where achieving a high-quality finish is essential.

Compared to traditional coated or bonded abrasives, non-woven materials provide several professional benefits:

• Consistent Surface Finish: The uniform fiber structure guarantees consistent wear and reliable outcomes over extensive surface areas.

• Reduced Loading and Longer Life: The porous design prevents clogging from debris, increasing both tool and abrasive durability.

• Cool Cutting Action: By dispersing heat more efficiently, non-woven abrasives help prevent burn marks, glazing, and metallurgical damage.

• Safer Operation: Their flexible design minimizes vibration and kickback, making them safer for handheld grinders and finishing tools.

• Versatility Across Materials: Suitable for use on metals, composites, plastics, and wood — ideal for mixed-material job sites.

Whether you’re blending weld seams, prepping for paint, or refining a finished surface, non-woven abrasives provide professional-grade consistency without the risk of overcutting or damaging your workpiece. For contractors, fabricators, and maintenance crews, that reliability means less downtime, cleaner results, and faster job completion.

Maximizing Performance & Longevity

To maximize the performance and lifespan of your non-woven abrasives, it’s essential to use them correctly within their specified operating conditions. These products work best with light to moderate pressure and consistent tool speed, allowing the abrasive grains to do their job without compressing or glazing the fibers.

Here are a few best practices to keep in mind:

• Match Tool Speed to the Abrasive’s Rating: Always verify RPM compatibility. Running too fast can cause premature wear, while running too slow can diminish cutting performance.

• Use Light Pressure: Excessive force compresses the fiber structure, generating heat and decreasing performance. Let the abrasive “float” and do the work.

• Keep Work Surfaces Clean: Periodically remove dust, residue, and metal particles to prevent buildup and ensure consistent surface results.

• Use Coolant or Airflow When Needed: For stainless steel, aluminum, or high-friction metals, using coolants or forced air can extend the life of tools and abrasives.

• Rotate and Reposition Frequently: Especially for belts and discs — even wear ensures consistent finishing and balanced operation.

• Store Properly: Store abrasives in a dry, temperature-controlled environment to prevent deterioration of bonding resins or fibers.

• Inspect Before Use: Inspect for wear, cracks, or uneven texture before installation. Damaged abrasives can impact finish quality and safety.

By following these best practices, you’ll not only extend the life of your abrasives but also maintain the high-quality finishes your projects require. A little attention to detail goes a long way toward smoother operations and less rework.

When finishing welds, removing oxidation, or giving a project that final brushed look, you need tools that work as hard as you do. At Hanes Supply, you’ll find non-woven abrasives designed for real-world construction and fabrication — bristle discs, flap brushes, belts, wheels, and more.

Explore our complete selection of abrasives to find the perfect product for your project. If you’re unsure which option best fits your application, our product specialists are ready to help you make the right choice and keep your workflow smooth.

Channellock® 426 Tongue and Groove Plier, 7/8 in Nominal, 3/4 in L C1080 High Carbon Steel Straight Jaw, 6-1/2 in OAL

Channellock® 426 Tongue and Groove Plier, 7/8 in Nominal, 3/4 in L C1080 High Carbon Steel Straight Jaw, 6-1/2 in OAL

Stanley® 33-716 FatMax® Reinforced Tape Rule with BladeArmor®, 16 ft L x 1-1/4 in W Blade, Mylar® Polyester Film Blade

Stanley® 33-716 FatMax® Reinforced Tape Rule with BladeArmor®, 16 ft L x 1-1/4 in W Blade, Mylar® Polyester Film Blade

Arrow™ HT50 Professional Heavy Duty Tomahawk Hammer Tacker, Flat Crown Staple

Arrow™ HT50 Professional Heavy Duty Tomahawk Hammer Tacker, Flat Crown Staple

Estwing® E324S Framing Hammer, 16 in OAL, Smooth Surface, 24 oz Steel Head, Straight Claw, Steel Handle

Estwing® E324S Framing Hammer, 16 in OAL, Smooth Surface, 24 oz Steel Head, Straight Claw, Steel Handle

Klein® D2000-9ST 2000 Heavy Duty Rebar Work Cutting Plier, 9-3/8 in OAL

Klein® D2000-9ST 2000 Heavy Duty Rebar Work Cutting Plier, 9-3/8 in OAL

DeWALT® Power-Stud®+ Powers® 7449SD1-PWR Expansion Wedge Anchor, 3/4 in dia, 10 in OAL, 7-1/2 in L Thread, Carbon Steel, Zinc Plated

DeWALT® Power-Stud®+ Powers® 7449SD1-PWR Expansion Wedge Anchor, 3/4 in dia, 10 in OAL, 7-1/2 in L Thread, Carbon Steel, Zinc Plated

BBI® 777037 All Threaded Rod, 3/8-16, 12 ft OAL, Steel Alloy

BBI® 777037 All Threaded Rod, 3/8-16, 12 ft OAL, Steel Alloy

BBI® 754072 Medium Split Lock Washer, 1/2 in Nominal, 18-8 SS

BBI® 754072 Medium Split Lock Washer, 1/2 in Nominal, 18-8 SS

Primesource® 8CTDSKR Sinker Nail, 17/64 in, 2-3/8 in L, 9 ga, Vinyl Coated, Smooth Shank

Primesource® 8CTDSKR Sinker Nail, 17/64 in, 2-3/8 in L, 9 ga, Vinyl Coated, Smooth Shank

Campbell® T3899724 Hitch Pin, 1/2 in dia, 4-1/4 in L Usable, Forged Steel, Zinc Plated with Yellow Chromate, 5 Grade

Campbell® T3899724 Hitch Pin, 1/2 in dia, 4-1/4 in L Usable, Forged Steel, Zinc Plated with Yellow Chromate, 5 Grade