Choosing the right saw blade is crucial for achieving clean, accurate, and efficient cuts. Whether you’re working with wood, metal, concrete, or other special materials, the blade you choose affects not only the quality of the finish but also the lifespan of your tool and how smoothly your job progresses. At Hanes Supply, we offer a wide variety of saw blades designed for nearly every cutting need — from heavy-duty industrial tasks to detailed finish work. We aim to help you find the blade that fits your tool, material, and project requirements.

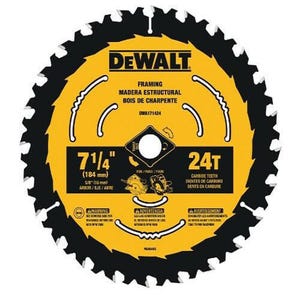

Circular Saw Blades

Circular saw blades are among the most commonly used cutting tools. These blades are designed for use with handheld circular saws, table saws, and miter saws, making them essential for woodworking, framing, cabinetry, and general construction applications.

• Applications: Typically used to cut wood, plywood, composites, plastics, and even certain metals with specialized blades.

• Variations:

- Fine-tooth blades make smooth, finish-ready cuts perfect for cabinetry or trim work.

- Ripping blades with fewer teeth cut faster through thick lumber and hardwoods.

- Combination blades offer the versatility to handle both ripping and crosscutting tasks easily.

• Features: Carbide-tipped teeth significantly extend blade lifespan, anti-kickback shoulders enhance safety, and thin-kerf designs minimize material waste.

Circular saw blades are essential components of most toolkits. Choosing the right type guarantees cleaner cuts, extended tool life, and less downtime for blade replacements.

Reciprocating Saw Blades

Reciprocating saw blades are valued for their versatility and power in demolition, remodeling, and rough-cutting tasks. They are often the preferred choice for contractors needing to make quick, aggressive cuts through tough materials.

• Applications: Best for demolition of wood, metal, PVC, drywall, plaster, and other construction materials.

• Specialty designs:

- Nail-embedded wood blades handle construction lumber embedded with screws or nails.

- Pruning blades have extra-wide gullets for quick outdoor cutting through tree limbs.

- Heavy-duty metal blades with bi-metal construction cut through steel, conduit, and pipe.

Reciprocating blades are designed for speed and durability, making them suitable when precision isn’t the priority but efficiency and toughness are.

Band Saw Blades

Band saw blades are essential in woodworking and metalworking shops. Their continuous loop design allows for long, smooth cuts with minimal waste.

• Applications: Cutting curves in wood, resawing lumber into boards, slicing plastics, or processing metals in fabrication shops.

• Tooth styles:

- Hook tooth blades cut aggressively through tougher materials.

- Skip tooth blades, clear chips easily and are best suited for softwoods or plastics.

- Variable pitch blades balance cutting speed with a smoother finish.

• Advantages: Band saw blades decrease material waste, allow for more complex shapes, and reduce the need for secondary finishing.

With the right blade, a band saw becomes one of the most versatile tools in the shop, capable of both rough cuts and fine detail work.

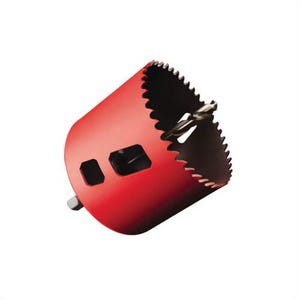

Hole Saw Blades

Hole saw blades are designed to cut precise holes in wood, metal, plastic, and masonry, removing only the material needed.

• Applications: Essential for plumbing, electrical, and HVAC installations to create clean, consistent openings.

• Blade types:

- Bi-metal hole saws for everyday cutting in wood and thin metal.

- Carbide-tipped models for tougher alloys and stainless steel.

- Diamond-grit saws for tile, stone, concrete, and glass.

• Advantages: A single hole saw eliminates the need for multiple drill bits, saving both time and money.

Hole saws are essential for professionals requiring precision and consistency in repetitive hole-cutting tasks.

Jig Saw Blades

Jigsaw blades are small, maneuverable, and great for curved or detailed cuts. They’re ideal for tasks where other saws can’t achieve the shapes you need.

• Applications: Flooring, cabinetry, furniture design, and even tile-cutting with specialty blades.

• Material-specific designs:

- Wood blades with coarse teeth for quick, rough cuts.

- Fine-tooth blades for laminate, thin plywood, or delicate veneers.

- Metal blades with high TPI for precise cuts in sheet metal or pipe.

For craftspeople, remodelers, and hobbyists, jigsaw blades enable precision and creativity.

Diamond Saw Blades

Diamond saw blades are designed for the most demanding jobs, with industrial-grade diamond particles embedded in the cutting edge.

• Applications: Best for cutting concrete, asphalt, masonry, tile, ceramics, and natural stone.

• Blade types:

- Wood blades with coarse teeth for quick, rough cuts.

- Fine-tooth blades for laminate, thin plywood, or delicate veneers.

- Metal blades with high TPI for precise cuts in sheet metal or pipe.

• Advantages: Unmatched cutting power, exceptional durability, and minimized heat buildup during use.

Diamond blades are vital for contractors, masons, and tile experts who require dependable performance when cutting the toughest materials.

Portable Band Saw Blades

Portable band saw blades offer the precise cutting of a stationary band saw combined with the ease of a handheld tool, making them essential for fieldwork.

• Applications: Cutting conduit, pipes, tubing, threaded rods, and structural steel.

• Performance: They’re especially popular in construction, maintenance, and repair jobs where mobility and clean cuts matter.

• Advantages: These blades provide precise cuts without the need for bulky stationary equipment, making them ideal for tight spaces and on-site jobs.

For contractors and tradespeople needing shop-quality results on the go, portable band saw blades are an excellent choice.

Choosing the Right Saw Blade for the Job

With so many types of blades available, selecting the right one can be overwhelming. Here are key factors to help narrow your choices:

Match to material: Always use a blade made for the specific material — wood, metal, masonry, or composites.

Tooth count (TPI or Teeth Per Inch): High TPI = smoother finish, slower cut. Low TPI = faster cut, rougher finish.

Kerf width: Thin-kerf blades use less power and remove less material, while thicker blades are better for tougher jobs.

Coatings and tips: Carbide or diamond-tipped blades last longer on tough jobs.

The right blade means better efficiency, cleaner cuts, and reduced tool wear.

Blade Maintenance and Safety Tips

Proper blade care helps extend performance and ensures safe operation:

• Inspect blades before use for dull edges, cracks, or missing teeth.

• Store blades properly — keep them dry, organized, and away from moisture.

• Use the proper speed and pressure for each material. Forcing a blade shortens its lifespan.

• Always wear proper PPE: safety glasses, gloves, and hearing protection.

• Replace worn blades quickly to ensure safety and optimal cutting.

• Well-maintained blades save money over time and enhance jobsite safety.

At Hanes Supply, we understand that the right saw blade makes all the difference. That’s why we offer a wide selection of blades for nearly every saw and material. From carbide-tipped circular saw blades to diamond-tipped masonry blades, our range guarantees you’ll find what you need to complete your project successfully.

Our team has decades of experience supplying contractors, manufacturers, and tradespeople. If you’re unsure which blade is right for your application, we’re here to assist.

Channellock® 426 Tongue and Groove Plier, 7/8 in Nominal, 3/4 in L C1080 High Carbon Steel Straight Jaw, 6-1/2 in OAL

Channellock® 426 Tongue and Groove Plier, 7/8 in Nominal, 3/4 in L C1080 High Carbon Steel Straight Jaw, 6-1/2 in OAL

Stanley® 33-716 FatMax® Reinforced Tape Rule with BladeArmor®, 16 ft L x 1-1/4 in W Blade, Mylar® Polyester Film Blade

Stanley® 33-716 FatMax® Reinforced Tape Rule with BladeArmor®, 16 ft L x 1-1/4 in W Blade, Mylar® Polyester Film Blade

Arrow™ HT50 Professional Heavy Duty Tomahawk Hammer Tacker, Flat Crown Staple

Arrow™ HT50 Professional Heavy Duty Tomahawk Hammer Tacker, Flat Crown Staple

Estwing® E324S Framing Hammer, 16 in OAL, Smooth Surface, 24 oz Steel Head, Straight Claw, Steel Handle

Estwing® E324S Framing Hammer, 16 in OAL, Smooth Surface, 24 oz Steel Head, Straight Claw, Steel Handle

Klein® D2000-9ST 2000 Heavy Duty Rebar Work Cutting Plier, 9-3/8 in OAL

Klein® D2000-9ST 2000 Heavy Duty Rebar Work Cutting Plier, 9-3/8 in OAL

DeWALT® Power-Stud®+ Powers® 7449SD1-PWR Expansion Wedge Anchor, 3/4 in dia, 10 in OAL, 7-1/2 in L Thread, Carbon Steel, Zinc Plated

DeWALT® Power-Stud®+ Powers® 7449SD1-PWR Expansion Wedge Anchor, 3/4 in dia, 10 in OAL, 7-1/2 in L Thread, Carbon Steel, Zinc Plated

BBI® 777037 All Threaded Rod, 3/8-16, 12 ft OAL, Steel Alloy

BBI® 777037 All Threaded Rod, 3/8-16, 12 ft OAL, Steel Alloy

BBI® 754072 Medium Split Lock Washer, 1/2 in Nominal, 18-8 SS

BBI® 754072 Medium Split Lock Washer, 1/2 in Nominal, 18-8 SS

Primesource® 8CTDSKR Sinker Nail, 17/64 in, 2-3/8 in L, 9 ga, Vinyl Coated, Smooth Shank

Primesource® 8CTDSKR Sinker Nail, 17/64 in, 2-3/8 in L, 9 ga, Vinyl Coated, Smooth Shank

Campbell® T3899724 Hitch Pin, 1/2 in dia, 4-1/4 in L Usable, Forged Steel, Zinc Plated with Yellow Chromate, 5 Grade

Campbell® T3899724 Hitch Pin, 1/2 in dia, 4-1/4 in L Usable, Forged Steel, Zinc Plated with Yellow Chromate, 5 Grade