Rigging hooks are indispensable in the lifting and rigging industry. They serve as the primary connection points between loads and lifting equipment. Their design, material, and functionality are critical to ensuring safe and efficient operations across various sectors, including construction, manufacturing, shipping, and more. At HSI, we offer a wide range of high-quality rigging hooks tailored to meet the diverse needs of our clients.

Types of Rigging Hooks

Understanding the different types of rigging hooks is essential for selecting the appropriate hardware for specific applications. Here are some of the most commonly used rigging hooks you’ll find in our catalog:

Eye Hooks

Eye hooks feature a circular opening at the top, known as the "eye," which allows for a permanent connection to slings or chains. This design offers flexibility in movement and positioning. However, the entire assembly may need replacement if the hook becomes damaged, as the eye connection is permanent. Eye hooks are versatile and commonly used in various industries, including construction and manufacturing.

Clevis Hooks

Clevis hooks have a U-shaped attachment point secured by a pin or bolt, enabling easy attachment and detachment from chains or other rigging components. This design allows for quick replacements if the hook is damaged without replacing the entire sling or chain assembly. Due to their ease of use and reliability, clevis hooks are widely used in industrial and manufacturing applications.

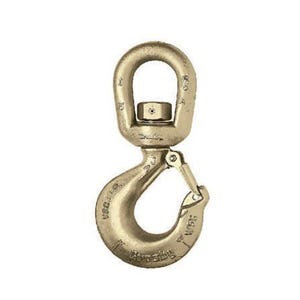

Swivel Hooks

Swivel hooks are designed to rotate, allowing the load to turn without twisting the lifting medium. There are two main types: positioning swivel hooks, which rotate to align during attachment but should not rotate under load, and true swivel hooks with bearings, which can rotate under load. Swivel hooks are essential in applications where cargo orientation is critical.

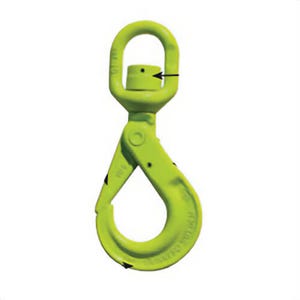

Self-Locking Hooks

Self-locking hooks automatically close and lock when a load is applied, providing an extra layer of safety by preventing accidental detachment. They are ideal for overhead lifting operations where safety is paramount. The automatic locking mechanism ensures that the hook remains securely closed until manually unlocked, reducing the risk of cargo release.

Sorting Hooks

Also known as lay-out hooks or shake-out hooks, sorting hooks have a wide throat opening, making them suitable for lifting and sorting flat plates, pipes, or other cylindrical items. They are typically used without a latch to facilitate easy attachment and detachment. Sorting hooks are commonly used in industries such as shipping and logistics for handling various materials.

Foundry Hooks

Foundry hooks, designed with a wide, deep throat, are used to lift items with handles or trunnions, such as molds or castings, in foundries. Due to their specific applications, which often involve high temperatures and the need for quick attachment, they are usually employed without a latch.

Grab Hooks

Grab hooks have a narrow throat that "grabs" onto a chain link to shorten or hold a length of chain. They are commonly used in load securement applications and are essential in adjusting chain lengths without the need for additional tools. Grab hooks are prevalent in transportation and towing industries.

Slip Hooks

Slip hooks, which feature a wider throat than grab hooks, are designed to allow chains or other attachments to slip through the hook. They are often used in applications where a more secure attachment is not necessary, such as towing or pulling. Slip hooks provide flexibility in various rigging setups.

J-Hooks and S-Hooks

J-hooks and S-hooks are simple hooks shaped like the letters J and S. They are used for various light-duty applications, such as hanging or supporting loads, and are not typically used for overhead lifting. These hooks are common in scenarios where quick and easy attachment is needed.

Applications of Rigging Hooks

Rigging hooks are utilized across a multitude of industries and applications:

• Construction: Lifting and positioning building materials, such as steel beams, concrete panels, and prefabricated components.

• Manufacturing: Handling heavy machinery parts, assembly line components, and raw materials.

• Shipping and Logistics: Loading and unloading cargo, securing loads during transport, and material handling in warehouses.

• Mining and Energy: Hoisting equipment, tools, and extracted materials in mines and oil rigs.

• Forestry: Lifting and transporting logs and forestry equipment.

Safety Considerations

Ensuring safety during lifting operations is paramount. Adhere to the following guidelines when using rigging hooks:

• Regular Inspections: Inspect hooks for signs of wear, deformation, cracks, or corrosion before each use. Remove any defective hooks from service immediately - the potential disaster is not worth the risk.

• Load Limits: Always be aware of the Working Load Limit (WLL) of the hook and ensure it is appropriate for the load being lifted. Never exceed the manufacturer's specified load limits.

• Proper Hook Selection: Choose the correct type of hook for the specific application, considering factors such as load type, lifting angle, and environmental conditions.

• Use of Safety Latches: Utilize hooks equipped with safety latches to prevent accidental detachment of the load. Ensure that the latch is functioning correctly before use.

• Avoid Side Loading: Apply loads only in the direction for which the hook is designed. Side loading can cause the hook to bend or fail.

• Training and Certification: Ensure that all personnel involved in rigging and lifting operations are properly trained and certified, understanding the correct use and limitations of rigging hardware.

Why Choose HSI for Your Rigging Hook Needs?

At HSI, we are committed to providing top-quality rigging hooks that meet industry standards and ensure safety and reliability. Our products are sourced from reputable manufacturers and are designed to withstand the rigors of heavy-duty applications. By choosing HSI, you benefit from:

Extensive Inventory: A wide selection of rigging hooks to suit various applications and load requirements.

A Rigging Library: You can find several catalogs with a wealth of information on our website, teaching you all you need to know!

Inspections: Our trained professionals can conduct inspections of all rigging equipment.

Rigging Training: We offer complete courses in all things rigging!

Get in touch with one of our rigging specialists today!

Channellock® 426 Tongue and Groove Plier, 7/8 in Nominal, 3/4 in L C1080 High Carbon Steel Straight Jaw, 6-1/2 in OAL

Channellock® 426 Tongue and Groove Plier, 7/8 in Nominal, 3/4 in L C1080 High Carbon Steel Straight Jaw, 6-1/2 in OAL

Stanley® 33-716 FatMax® Reinforced Tape Rule with BladeArmor®, 16 ft L x 1-1/4 in W Blade, Mylar® Polyester Film Blade

Stanley® 33-716 FatMax® Reinforced Tape Rule with BladeArmor®, 16 ft L x 1-1/4 in W Blade, Mylar® Polyester Film Blade

Arrow™ HT50 Professional Heavy Duty Tomahawk Hammer Tacker, Flat Crown Staple

Arrow™ HT50 Professional Heavy Duty Tomahawk Hammer Tacker, Flat Crown Staple

Estwing® E324S Framing Hammer, 16 in OAL, Smooth Surface, 24 oz Steel Head, Straight Claw, Steel Handle

Estwing® E324S Framing Hammer, 16 in OAL, Smooth Surface, 24 oz Steel Head, Straight Claw, Steel Handle

Klein® D2000-9ST 2000 Heavy Duty Rebar Work Cutting Plier, 9-3/8 in OAL

Klein® D2000-9ST 2000 Heavy Duty Rebar Work Cutting Plier, 9-3/8 in OAL

DeWALT® Power-Stud®+ Powers® 7449SD1-PWR Expansion Wedge Anchor, 3/4 in dia, 10 in OAL, 7-1/2 in L Thread, Carbon Steel, Zinc Plated

DeWALT® Power-Stud®+ Powers® 7449SD1-PWR Expansion Wedge Anchor, 3/4 in dia, 10 in OAL, 7-1/2 in L Thread, Carbon Steel, Zinc Plated

BBI® 777037 All Threaded Rod, 3/8-16, 12 ft OAL, Steel Alloy

BBI® 777037 All Threaded Rod, 3/8-16, 12 ft OAL, Steel Alloy

BBI® 754072 Medium Split Lock Washer, 1/2 in Nominal, 18-8 SS

BBI® 754072 Medium Split Lock Washer, 1/2 in Nominal, 18-8 SS

Primesource® 8CTDSKR Sinker Nail, 17/64 in, 2-3/8 in L, 9 ga, Vinyl Coated, Smooth Shank

Primesource® 8CTDSKR Sinker Nail, 17/64 in, 2-3/8 in L, 9 ga, Vinyl Coated, Smooth Shank

Campbell® T3899724 Hitch Pin, 1/2 in dia, 4-1/4 in L Usable, Forged Steel, Zinc Plated with Yellow Chromate, 5 Grade

Campbell® T3899724 Hitch Pin, 1/2 in dia, 4-1/4 in L Usable, Forged Steel, Zinc Plated with Yellow Chromate, 5 Grade