Rotor Lift Ergonomic Improvement

- By Hanes Supply

- Mar 20, 2004

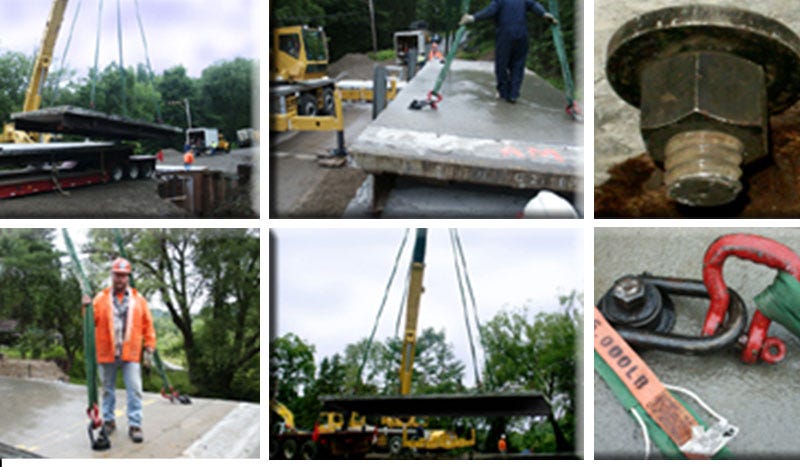

An Electric Power Producer needed to update the Rigging for their 80 ton Rotor. Hanes Supply conducted an on-site review with Engineering and Rigging Superintendents resulting in the following recommendations. Wire Rope Slings to be replaced with TwinPath High Performance Slings. To accomplish this, the following was required:

Top Rigging:

2 each TPXC 10,000 x 10’ with special 2” Alloy Oblong Links each end, with Load Bars. Capacity; Vertical at 100,000 lb and Basket at 200,000 lb

Bottom Rigging:

2 each TPXC 12,500 x 11’. Capacity; Vertical at 125,000 lb and Basket at 250,000 lb

4 each Crosby S-253 “Sling Saver” Synthetic Shackles. Capacity at 35 ton

4 each Crosby G-209 Galvanized Shackles. Capacity at 35 ton

2 each “Quick” Removable Wear Pads for TPCX 12,500 x 36”

4 each Special Washers for existing Lifting Beam, width 0.75” “Thick II” 4.25” diameter center hole. 5.5” center to round top. 4.5” center to flat bottom.

Our customer was extremely pleased with the ergonomics of their New Rigging.

PROJECT DETAILS

LOCATION

Buffalo, NY

DATE

March 2001

RIGGING

(2) TPXC 10,000 x 10’

(2) TPXC 12,500 x 11’

(4) Crosby S-253 “Sling Saver” Synthetic Shackles

(4) Crosby G-209 Galvanized Shackles

(2) “Quick” Removable Wear Pads for TPCX

(4) Special Washers for existing Lifting Beam

Top Rigging:

2 each TPXC 10,000 x 10’ with special 2” Alloy Oblong Links each end, with Load Bars. Capacity; Vertical at 100,000 lb and Basket at 200,000 lb

Bottom Rigging:

2 each TPXC 12,500 x 11’. Capacity; Vertical at 125,000 lb and Basket at 250,000 lb

4 each Crosby S-253 “Sling Saver” Synthetic Shackles. Capacity at 35 ton

4 each Crosby G-209 Galvanized Shackles. Capacity at 35 ton

2 each “Quick” Removable Wear Pads for TPCX 12,500 x 36”

4 each Special Washers for existing Lifting Beam, width 0.75” “Thick II” 4.25” diameter center hole. 5.5” center to round top. 4.5” center to flat bottom.

Our customer was extremely pleased with the ergonomics of their New Rigging.

PROJECT DETAILS

LOCATION

Buffalo, NY

DATE

March 2001

RIGGING

(2) TPXC 10,000 x 10’

(2) TPXC 12,500 x 11’

(4) Crosby S-253 “Sling Saver” Synthetic Shackles

(4) Crosby G-209 Galvanized Shackles

(2) “Quick” Removable Wear Pads for TPCX

(4) Special Washers for existing Lifting Beam

Klein® D2000-9ST 2000 Heavy Duty Rebar Work Cutting Plier, 9-3/8 in OAL

Klein® D2000-9ST 2000 Heavy Duty Rebar Work Cutting Plier, 9-3/8 in OAL

Stanley® FatMax® 33-716 Reinforced Tape Rule with BladeArmor®, 16 ft L x 1-1/4 in W Blade, Mylar® Polyester Film Blade

Stanley® FatMax® 33-716 Reinforced Tape Rule with BladeArmor®, 16 ft L x 1-1/4 in W Blade, Mylar® Polyester Film Blade

Channellock® 426 Tongue and Groove Plier, 7/8 in Nominal, 3/4 in L C1080 High Carbon Steel Straight Jaw, 6-1/2 in OAL

Channellock® 426 Tongue and Groove Plier, 7/8 in Nominal, 3/4 in L C1080 High Carbon Steel Straight Jaw, 6-1/2 in OAL

Estwing® E324S Framing Hammer, 16 in OAL, Smooth Surface, 24 oz Steel Head, Straight Claw, Steel Handle

Estwing® E324S Framing Hammer, 16 in OAL, Smooth Surface, 24 oz Steel Head, Straight Claw, Steel Handle

Mayhew™ 62065 X-Long Pin Punch Kit, Hex Shank, 9-1/2 in OAL, 5 Pcs

Mayhew™ 62065 X-Long Pin Punch Kit, Hex Shank, 9-1/2 in OAL, 5 Pcs

DeWALT® Power-Stud®+ Powers® 7449SD1-PWR Expansion Wedge Anchor, 3/4 in dia, 10 in OAL, 7-1/2 in L Thread, Carbon Steel, Zinc Plated

DeWALT® Power-Stud®+ Powers® 7449SD1-PWR Expansion Wedge Anchor, 3/4 in dia, 10 in OAL, 7-1/2 in L Thread, Carbon Steel, Zinc Plated

BBI® 777037 All Threaded Rod, 3/8-16, 12 ft OAL, Steel Alloy

BBI® 777037 All Threaded Rod, 3/8-16, 12 ft OAL, Steel Alloy

Campbell® T3899724 Hitch Pin, 1/2 in dia, 4-1/4 in L Usable, Forged Steel, Zinc Plated with Yellow Chromate, 5 Grade

Campbell® T3899724 Hitch Pin, 1/2 in dia, 4-1/4 in L Usable, Forged Steel, Zinc Plated with Yellow Chromate, 5 Grade

Primesource® 8CTDSKR Sinker Nail, 17/64 in, 2-3/8 in L, 9 ga, Vinyl Coated, Smooth Shank

Primesource® 8CTDSKR Sinker Nail, 17/64 in, 2-3/8 in L, 9 ga, Vinyl Coated, Smooth Shank

BBI® 754072 Medium Split Lock Washer, 1/2 in Nominal, 18-8 SS

BBI® 754072 Medium Split Lock Washer, 1/2 in Nominal, 18-8 SS